Jan 26, 2009 - Office 2007(.iso)(Eng)(Multi-App DVD)(W/Keygen). Printing press pro extreme 7.0 free download free. Office PowerPoint 2007 Office Professional Plus 2007 Office Project Professional.

- Jeff Wimmer Ultimate Tech Manual

- Jeff Wimmer Ultimate Tech Manual Free

- Jeff Wimmer Ultimate Tech Manual 2020

- Jeff Wimmer Ultimate Tech Manual Pdf

- Jeff Wimmer Ultimate Tech Manual 2019

Jeff Wimmer Ultimate Tech Manual Youtube 'I can remember back in early 2000, when Jeff sat in my living room working on his very first Tech Manual, Volume I. He had flown into Seattle to visit his little sister and while he had down time, worked tirelessly trying to finish the content. Installation: Jeff wimmer ultimate tech manual. Jun 17, 2016 Tags: FSX IRIS C27 Spartan FSX landing airport airshow google. Game Microsoft Flight Simulator X; 2006.

Flexographic Image Reproduction Specifications & Tolerances (FIRST) 6.0 provides all members of the flexographic supply chain with the technical information needed to produce high-quality and consistent print, pressrun after pressrun.

Wimmer notes that he has also been diving with sharks in Fiji and set a world record by executing the world's first tandem skydive above Mount Everest. 'I want to write the manual rather than. The printing revolution Elizabeth Eisenstein The Printing Revolution In Early Modern Europe PdfGoss (Hist 5040 - Spring 1999). Jeff wimmer ultimate tech manual This exclusive edition is designed to help you implement the best Comprehensive Preventative Maintenance Program for your facility. The printing revolution in early modern europe.

FIRST seeks to understand customers' graphic requirements for reproduction and translates those aesthetic requirements into specifications for each phase of the flexographic printing process, including: customers, designers, prepress providers, raw material and equipment suppliers, and printers. Its intention is to provide all participants in the flexographic reproduction process with a common set of guidelines, tutorials and data to be used as communication and production tools.

FIRST Is a Set of Specifications, Not Standards

When followed, these specifications facilitate producing a predictable, consistent result. The process and specifications supported intend:

To improve quality and consistency through improved communication and measurement procedures.

To reduce cycle time and minimize rework through improved process control methodology.

To control production costs through streamlined raw materials and process improvement methodology.

To grow the overall flexographic printing industry through increased market share of an expanding market.

To outline key flexographic procedures and guidelines to be used throughout the process, including during implementation, design, prepress and printing.

To enable CPCs to obtain optimal flexographic print quality, which equals or exceeds offset lithography and gravure printing.

- To improve quality and consistency through improved communication and measurement procedures.

- To reduce cycle time and minimize rework through improved process control methodology.

- To control production costs through streamlined raw materials and process improvement methodology.

- To grow the overall flexographic printing industry through increased market share of an expanding market.

- To outline key flexographic procedures and guidelines to be used throughout the process, including during implementation, design, prepress and printing.

- To enable CPCs to obtain optimal flexographic print quality, which equals or exceeds offset lithography and gravure printing.

What's Inside FIRST 6.0?

Communication is the foundation of FIRST. Using agreed upon terminology and a defined workflow, FIRST seeks to minimize miscommunication and promote the manufacture of consistent, conforming flexographic materials. To that end, the communication and implementation section of FIRST provides the reader with a solid understanding of what they will find throughout the rest of the FIRST Document. They will learn more about internal and external communication practices, while focusing heavily on FIRST Methodology—optimization, fingerprinting, process control, characterization and process improvement.

Graphic designers will find value in FIRST‘s design section, as it was assembled to assist in producing packaging graphics specific to the flexographic industry. This section teaches designers the basics of getting started and recognizing the attributes of flexographic printing. It also educates them on specific type and design elements, digital photography parameters, document structure and format, specific file formats and their usages, as well as preflighting tips for the final design prior to release to the printer. In addition, FIRST offers a free Design Guide, available to download and share with design partners.

Jeff Wimmer Ultimate Tech Manual

The prepress section provides graphic artists with the tools necessary to perform their daily job functions at their absolute best. Throughout this section, prepress experts will find data, tutorials and common practices that will help enhance their daily workflows. These practices include electronic/digital file formats used, as well as job assembly practices to include image trapping, text and graphic elements, vignettes/gradations, bar code considerations and template layout. The prepress section also covers process color calibration techniques, file output parameters, color proofs and general printing plate specifications.

The printer is responsible for reproducing a design accurately and consistently, both throughout the pressrun and between pressruns. The ability of the printer to measure and control their process directly impacts the quality of the printed piece, the efficiency of the pressrun and the overall time-to-market of the new product. Throughout this section, the printer learns more about print evaluation and the measurement tools used to control process color print characteristics, and develops an understanding of press component print variables and job-specific print variables, including substrates, inks and other pressroom consumables. The printer will also determine the best operating parameters for its ink metering system, plate package and press settings, all while learning common testing procedures performed during the production process.

From 'abnormal color vision' to 'Zahn Cup,' FIRST 6.0 features an all-encompassing glossary section which includes concise definitions for more than 400 common industry terms, acronyms and other flexography jargon.

The appendix section includes vital contact information for other industry organizations, a completely revamped reference standards and specifications section, a quick-reference section for the control and test targets used throughout the book, as well as other useful information.

What Do People Think About FIRST?

Jeff Wimmer Ultimate Tech Manual Free

'FIRST is the most comprehensive printing document on the planet. It provides communication tools and best practices to align an entire supply chain with customers' expectations. Avant garde black fonts. FIRST is why the flexo industry is growing globally, as the best printing process known to man!'

You must be logged in to post a comment. An octoroon pdf.

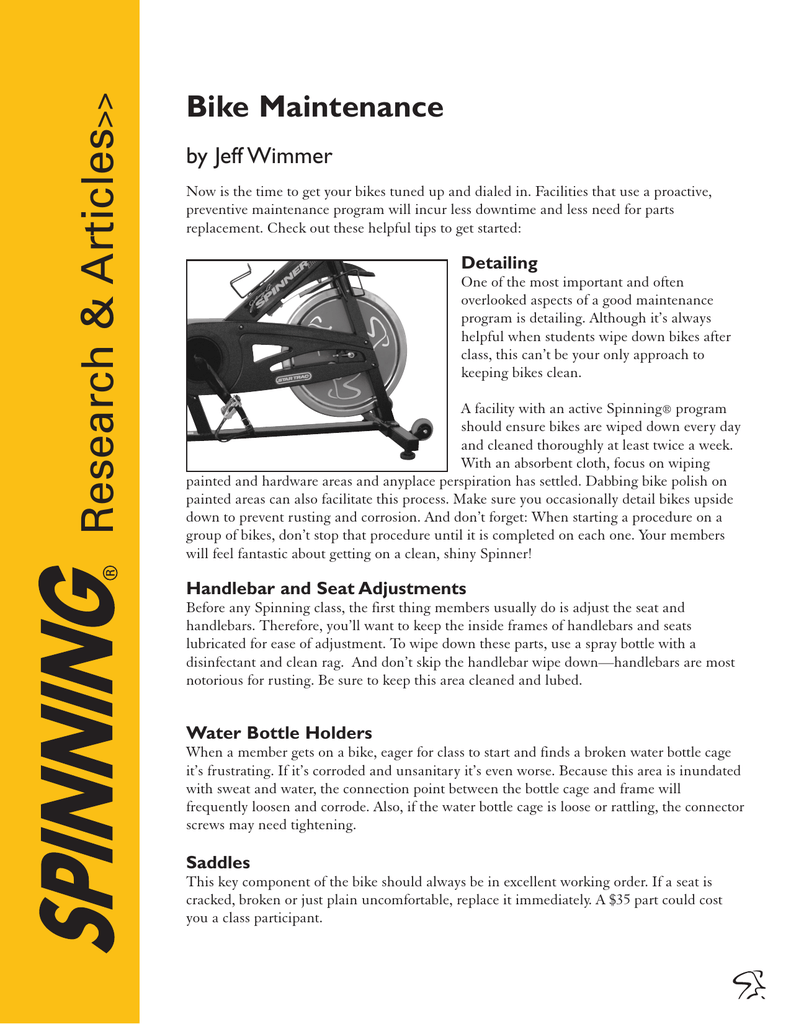

By Jennifer Sage On August 18, 2013Under MiscI'm so so saddened by the news of the passing of Jeff Wimmer today. The indoor cycling industry will not be the same without him. If you are a Spinning® (or any indoor cycling program) instructor, even if you never heard of Jeff, you most likely benefitted in some way from his expertise. He knew more about every kind of bike in this industry than anyone else…in the world! He lovingly assembled and repaired more bikes than anyone in the world. He wrote the book (literally) on how to maintain these bikes (your club might have his book on hand in their maintenance department). He taught instructors at WSSC and other conferences how to take the BEST care of their bikes.

Jeff found a niche that wasn't being serviced, developed an expertise that was so far and away beyond anyone else in this industry, and created a thriving business. Based out of California, but he covered the whole country. Manufactures of most indoor bikes knew about Jeff, and some even consulted with him and asked his advice on their product. Now that is admirable in this competitive world of fitness! He was THE man for every single (reputable) bike in this industry. He had the best warranty (lifetime) and highest integrity of anyone in the industry. He stood behind his word. And, he was passionate about what he was doing, it was very obvious.

Jeff Wimmer Ultimate Tech Manual

The prepress section provides graphic artists with the tools necessary to perform their daily job functions at their absolute best. Throughout this section, prepress experts will find data, tutorials and common practices that will help enhance their daily workflows. These practices include electronic/digital file formats used, as well as job assembly practices to include image trapping, text and graphic elements, vignettes/gradations, bar code considerations and template layout. The prepress section also covers process color calibration techniques, file output parameters, color proofs and general printing plate specifications.

The printer is responsible for reproducing a design accurately and consistently, both throughout the pressrun and between pressruns. The ability of the printer to measure and control their process directly impacts the quality of the printed piece, the efficiency of the pressrun and the overall time-to-market of the new product. Throughout this section, the printer learns more about print evaluation and the measurement tools used to control process color print characteristics, and develops an understanding of press component print variables and job-specific print variables, including substrates, inks and other pressroom consumables. The printer will also determine the best operating parameters for its ink metering system, plate package and press settings, all while learning common testing procedures performed during the production process.

From 'abnormal color vision' to 'Zahn Cup,' FIRST 6.0 features an all-encompassing glossary section which includes concise definitions for more than 400 common industry terms, acronyms and other flexography jargon.

The appendix section includes vital contact information for other industry organizations, a completely revamped reference standards and specifications section, a quick-reference section for the control and test targets used throughout the book, as well as other useful information.

What Do People Think About FIRST?

Jeff Wimmer Ultimate Tech Manual Free

'FIRST is the most comprehensive printing document on the planet. It provides communication tools and best practices to align an entire supply chain with customers' expectations. Avant garde black fonts. FIRST is why the flexo industry is growing globally, as the best printing process known to man!'

You must be logged in to post a comment. An octoroon pdf.

By Jennifer Sage On August 18, 2013Under MiscI'm so so saddened by the news of the passing of Jeff Wimmer today. The indoor cycling industry will not be the same without him. If you are a Spinning® (or any indoor cycling program) instructor, even if you never heard of Jeff, you most likely benefitted in some way from his expertise. He knew more about every kind of bike in this industry than anyone else…in the world! He lovingly assembled and repaired more bikes than anyone in the world. He wrote the book (literally) on how to maintain these bikes (your club might have his book on hand in their maintenance department). He taught instructors at WSSC and other conferences how to take the BEST care of their bikes.

Jeff found a niche that wasn't being serviced, developed an expertise that was so far and away beyond anyone else in this industry, and created a thriving business. Based out of California, but he covered the whole country. Manufactures of most indoor bikes knew about Jeff, and some even consulted with him and asked his advice on their product. Now that is admirable in this competitive world of fitness! He was THE man for every single (reputable) bike in this industry. He had the best warranty (lifetime) and highest integrity of anyone in the industry. He stood behind his word. And, he was passionate about what he was doing, it was very obvious.

Photo: Jeff training instructors in a bicycle maintenance session at WSSC

Although he was very busy, he would always take time to talk to me when I called with questions. It wasn't often, but he always appreciated what I was doing in the industry. When I had to quickly transition from the uncomfortable situation I found myself in at my previous company 2-1/2 years ago, and then created ICA, he supported me 100%. He told me many times that the industry needed what I was offering (you can only imagine he had seen some pretty crazy stuff out there!) I'd been intending on writing an article on ICA this fall about his business Studio Cycles, his website BikeTekUSA and his blog (which provides some great training videos with advice for instructors).

A few years ago when my mother-in-law was recovering from a broken hip and decided to get a Spinner bike for her recovery (she didn't live anywhere near a gym, nor is she the type to go anywhere near a gym), Jeff gave me an incredible deal (translation: he didn't make a penny) on an entry-level bike and shipped it to her. He didn't have to do this, he had many clients ordering dozens of bikes at a time, lucrative orders that demanded his time, but he went out of his way for us. She rode that bike often and sped up her recovery as a result.

Last year at IDEA Shirin Beckett contacted Jeff about getting just one bike for our booth, and he again went out of his way for us. There was nothing in it for him, but that's not how Jeff worked. He believed in ICA and wanted to help us!

Our industry has lost a shining star. These are shoes that cannot be filled.

It made me think long and hard this morning. We all go through our lives day-in, day-out…we are overly busy, sometimes happy, sometimes sad, stressed, whatever… But somewhere else, someone may be going through deep pain and debilitating depression, and we have no idea what they are going through. It made me very sad.

Dear Jeff, I hope you have found peace now, and are riding your Spinning bike daily! We will miss you forever!

Jeff Wimmer Ultimate Tech Manual 2020

NOTE: If you do any maintenance on your bikes, or your club needs better maintenance on your bikes, please go buy his manual if you do not already have one. They are the BIBLE for indoor bicycle maintenance, an absolute must-have for every single facility with a cycling program. I am sure Jeff's family will be needing some extra financial support during this very difficult time, so your purchase now will not only help you and your club immensely, but also Jeff's family.

Jeff Wimmer Ultimate Tech Manual Pdf

(Photos from Studio Cycles website)

Edit: the beautiful image below was created by Luca Giannolo and posted to a Facebook Spinning forum for Lisa Martines, Jeff's former girlfriend who still loved and supported him. My heart goes out to Lisa and to Jeff's family.

Jeff Wimmer Ultimate Tech Manual 2019

Thank you Luca for a beautiful tribute.